Znanstveno stručni simpozij

grafičara Blaž Baromić, Senj, Hrvatska ,19. – 21. lipnja 2003; Zbornik

radova

RELATION OF BOARD BOX STRENGTH AND GRAIN DIRECTION

Darko Babić; V. Vančina-Kropar; B. Lajić

Faculty of Graphic Arts in Zagreb

Getaldićeva 2

10000 Zagreb

darko.babic4@zg.tel.hr

ABSTRACT

Modern food, chemical, and pharmaceutical industry pack their products

in big transport corrugated board boxes, but they also use small board

boxes for individual commercial packaging. It is a common practice to

make the grain direction of those small folding board boxes parallel

to the box height, which creates large amounts of useless waste material

in their production process in the graphic industry. This adds to box

prices, but it also has negative consequences for the environment protection

because it increases board consumption per box. The grain direction

of big transport boxes is not the issue, but if this research proves

that the folding board box strength is only slightly different when

different height and grain dispositions are taken into account, and

if the machines used in the production process react in the same way

to those box types, we might be able to recommend to the graphic industry

a new way of producing such boxes. The new production system would make

a better use of board sheets by changing the grain direction, which,

in turn, would make the production cheaper and would be ecologically

better.

Key words: BCT-test, box blanks, tensile breaking

strength, grain direction

1. INTRODUCTION

The bearing capacity of small board boxes, which are closed by sticking,

is very important, especially in aesthetic way. Although all the board

boxes producers know that the grain direction in these boxes is parallel

with the height of the box, we have started to investigate the bearing

capacity of the box with the grain direction perpendicular its height.

In this investigation, the attention has not been paid to the appearance

of the grooves, which could look somewhat different because of the change

of grain direction, but one wanted to find out the bearing capacity

of such small boxes produced from boards. The boards of 250 g/m2 of

different qualities were varied. Somewhat lighter board than usually

used was chosen, with the intention that the strength of the material

itself participates as little as possible in the obtained result.

2. EXPERIMENTAL

2.1 Materials

We have examined 4 commercial boards of nominal grammage 250 g/m2..

The boards were produced as two- and three-layer boards, composed

of woodfree (virgin cellulose fibres), CTMP and recycled fibres. Only

the board No 2 was coated. The structure and description of investigated

boards are presented in Table 1.

| Number of Board |

Composition |

Description |

| 1 |

2 |

3 |

| 1 |

two-layer

upper: woodfree, coated

lower: recycled fibre, uncoated

|

Chromo-board

for

packaging

|

| 2 |

three-layer

upper, lower: woodfree, coated

middle: CTMP fibre

coated

|

Voluminous chromo-board

for special

packaging

|

| 3 |

two-layer

upper: woodfree, coated

lower: recycled fibre, uncoated

|

Graphic and

packaging board

|

| 4 |

two-layer, uncoated

recycled fibre, bleached (white)

|

Graphic and

packaging board

|

Table 1. Structure and description of commercial board grades

(250 g/m2)

2.2 Methods

Samples of all investigated boards were conditioned at 23 oC

and 50 % RH before the measuring of basic and mechanical properties,

done by using standard methods.

The following properties of boards were measured:

basic: thickness/caliper (ISO 534), grammage (ISO 536) and mechanical:

tensile breaking strength and tensile elongation/tensile strain (ISO

1924/2).

Relatively small boxes were made/produced from investigated boards;

30 boxes of each board (all together 120 boxes),

15 with grain direction parallel with the height of the box, and

15 with grain direction perpendicular to the height of the box.

The grain direction (MD) was marked by the letter A and

the cross grain direction (CD) was marked by the letter B.

The boxes were produced according to the following blank design:

a) the height of 150 mm and the ground plan of 50 x 50 mm,

b) the height of 200 mm and the ground plan of 50 x 50 mm,

c) the height of 200 mm and the ground plan of 70 x 70 mm.

The box blanks were done on plotter – cutter Premium line CM 1320,

Congsberg System (Norway) and cutting of box blanks is presented in

Figure 1.

Figure 1. Cutting of box blanks on plotter –

cutter

Premium line CM 1320

Figure 2. Investigated box blanks

In figure 2 some of investigated box blanks are presented.

The box blanks were glued together by hot-melt polyurethane adhesive

in order to avoid, eventual, weakening of the glued connections and

at the same time false results of box strengths were avoided too.

The testing of box strength was performed by the BCT method and the

compression tester Acquati (Milan, Italy) was used (Figure 3).

We tested 5 boxes with grain direction (A) parallel with the height

of the box and 5 boxes with grain (B) direction perpendicular to the

height of the box for each board and each blank design (a, b and c).

Figure 3. Testing of box strength by tester Acquati (Milan)

Figure 4. The look of the box after BCT testing

During the squeezing, the boxes were deformed up to the stopping

of the computer-aided tester at the moment when the first plastic

deformation of box was achieved. The look of box after BCT/compression

is shown in Figure 4.

3. RESULTS

From the results of thickness (20 test pieces were measured for each

board) and grammage (also 20 test pieces were measured for each board)

specific volume (v) was calculated for all investigated boards. The

results are given in Table 2.

In the same table the results of tensile breaking strength and tensile

elongation (tensile strain) of investigated boards are presented.

Obtained results are mean values of 10 tests done in grain direction

(A) and 10 tests in direction perpendicular to grain direction (B),

as well as, standard deviations.

| No of testing |

Board |

Specific

Volume

[cm3 g-1]

|

Grain direction |

Tens.

Streng.

[N]

|

Difference of the A and B direction tensile breaking

strength (%) |

|

Tens.

Elong.

[%]

|

|

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 1 |

1 |

1,17 |

A |

254,90 |

40,92 |

33,084 |

1,14 |

0,347 |

| 2 |

B |

101,90 |

2,331 |

3,24 |

0,389 |

| 3 |

2 |

1,51 |

A |

290,70 |

62,84 |

10,667 |

1,81 |

0,630 |

| 4 |

B |

182,70 |

5,437 |

2,79 |

0,268 |

| 5 |

3 |

1,13 |

A |

285,80 |

57,20 |

12,653 |

1,97 |

0,357 |

| 6 |

B |

163,50 |

5,563 |

3,53 |

0,377 |

| 7 |

4 |

1,17 |

A |

163,77 |

57,21 |

12,736 |

1,17 |

0,190 |

| 8 |

B |

93,70 |

3,466 |

2,06 |

0,133 |

Table 2. Tensile breaking strength and tensile

elongation (tensile strain) of investigated boards

The results of box strength performed by the BCT method are presented

in Table 3.

| |

|

|

|

|

|

| 1 |

2 |

3 |

4 |

5

|

6 |

| 1 |

1 |

A |

50x50x150 |

116

|

81,03 |

| 2 |

B |

94 |

| 3 |

A |

50x50x200 |

120

|

85,00

|

| 4 |

B |

102 |

| 5 |

A |

70x70x200 |

120

|

96,66 (3,34)

|

| 6 |

B |

116 |

| 7 |

2 |

A |

50x50x150 |

220

|

85,45

|

| 8 |

B |

188 |

| 9 |

A |

50x50x200 |

198

|

84,84

|

| 10 |

B |

168 |

| 11 |

A |

70x70x200 |

222

|

86,48

|

| 12 |

B |

192 |

| 13 |

3 |

B |

50x50x150 |

108

|

88,88

|

| 14 |

A |

96 |

| 15 |

B |

50x50x200 |

104

|

80,76

|

| 16 |

A |

84 |

| 17 |

B |

70x70x200 |

102

|

88,23

|

| 18 |

A |

90 |

| 19 |

4 |

A |

50x50x150 |

98

|

65,53 (34,47)

|

| 20 |

B |

64 |

| 21 |

A |

50x50x200 |

84

|

76,61

|

| 22 |

B |

64 |

| 23 |

A |

70x70x200 |

102 |

68,72 |

| 24 |

B |

70 |

Table 3. Results of the box strength

RESULTS ANALYSIS

From the results of the measuring, shown in table 2, it can

be concluded that our hypothesis proved correct and that the tested

board tensile elongation is almost twice as high in the grain direction

than it is transversely to them. This can be read from table 1, columns

6 and 8. It is evident from column 8, which shows the tensile elongation

of board, that the elongation is always greater in the direction transverse

to the grain direction. Table 2 also shows that the board tested does

not differ at all from the accepted standards of the material used

for the production of board folding boxes. Table 3 gives the BCT test

results, according to the grain direction and the box height. We tried

to establish weather the results for a bigger plan view surface and

a higher box with the same plan view surface differ greatly. The analysis

of table 3, column 6 shows that the smallest ratio (3.34%) was detected

in the first box (dimensions 70x70x200) and the biggest (34.47%) in

box 4 (dimensions 50x50x150). Other indicators and comparisons are

not consistent in their results regarding the relation of the box

height and strength. The results of the research focusing on the relation

of the plan view of a box and its strength are equally inconsistent,

so the only conclusion to be drawn from it is that the strength of

a box cannot be determined by cardboard quality. This is shown by

table 2, where the results for the tensile strength of different board

types are the same as those given in table 4, column 2, whereas the

compression strength results, given in column 3, are completely different.

The general conclusion to be drawn from the research is that the compression

strength of the boxes does not differ greatly in relation to the change

of grain direction (34.47% at the most), which confirms our initial

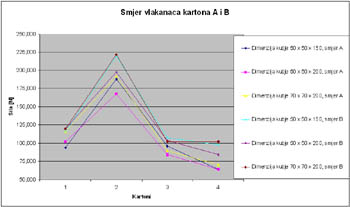

hypothesis. The conclusion is supported by figure 5, showing the correlations

of grain directions, box

(Kliknuti

na sliku za bolji prikaz)

Figure 5: Simultaneous representation of board types and

compression strength of finished boxes, according to their grain direction

dimensions, and board types. The logical continuation of the research

would be the testing of the boxes in an automatic packaging machine.

If the obtained results turn out to be similar to those of our research,

we could advise the graphic industry to reconsider the traditional

way of making cardboard boxes with fibres parallel to the box height.

This would enable us to save much material, because box blanks in

a cardboard sheet would be placed in such a way as to make maximum

use of material and the waste quantity would be reduced, which would

help protect the environment by reducing paper consumption.

| Cardboard |

Tearing strength scale |

Compression strength scale |

| 1 |

2 |

3 |

| 1 |

4 |

2 |

| 2 |

1 |

1 |

| 3 |

2 |

3 |

| 4 |

3 |

4 |

Table 5: Cardboard quality scales comparison

We want to thank Holding Bilokalnik Factory IPA, especially its CEO,

engineer Mr. Španiček, and the head of its Central Laboratory, Mrs

Franjka Stojević, engineer, who helped us greatly with the box blanks

making and measuring of the results.

LITERATURE

M. Černič-Letnar, Papir za fleksibilno embalažo, Papir,

št. 1-2 (1966)9-12.

M. Černič-Letnar, Papir, karton, lepenka, valoviti karton, Ljubljana:

Inštitut za celulozo in papir, Seminarsko gradivo, 1999.

M. Černič-Letnar, Kakovost embalažnega kartona iz valovite lepenke,

Ljubljana: Inštitut za celulozo in papir, Seminarsko gradivo, 1999.

V. Kropar-Vančina, M. Černič-Letnar, Durability of coated and

uncoated boards, J. A. Bristow (Ed), Advances in Printing Science

and Technology, Pira International Ltd, Leatherhead 2001, 41-55.,

ISBN 1 85802 438 2

M. Černič-Letnar, V. Kropar-Vančina, The effect of accelerated

ageing on graphic paperboards dergradation, Restaurator, 2002, 118-132.

V. Vančina, M. Mikota, A. Golubović, Utjecaj vlage na krutost

nekih premazanih kartona, Acta Graph. 4 (1992) 199-203.

Marjeta Černič Letnar, Aleš Hladnik, Vesna Kropar Vančina, Effect

of Accelerated Ageing on Degradation of Unprinted and Printed Graphic

Paperboards, 29 th International IARIGAI Research Conference, Proceedings,

Advances in Graphic Arts Media Technology, Session 3 Quality Control.

D. Babić, V. Vančina, M. Mikota, A. Golubović, B. Lajić, Kvaliteta

žlijebljenja u ovisnosti o krutosti, Zbornik radova s 12. znanstveno-stručnog

simpozija Intergrafika '93, Grafički fakultet Sveučilišta u Zagrebu

i Revija Acta Graphica, Zagreb 1993, 212-220.

M. Černič-Letnar, V. Kropar-Vančina, L. Scheicher, Optična obstojnost

grafičnih kartonov, Grafičar, 2 (2001) 14-23.

M. Černič-Letnar, V. Kropar-Vančina, Vpliv sestave in površinske

obdelave grafičnih kartonov na optično in barvno obstojnost, Papir,

3-4 (2001) 69-76.

M. Černič-Letnar, L. Scheicher, V. Kropar-Vančina, Optična in

barvna obstojnost grafičnih kartonov in laboratorijskih odtisov, Zbornik

predavanj, 27. mednarodnog letnog simpozija DITP, Bled, Slovenija,

2000., 133-140.

V. Vančina, M. Mikota, A. Golubović, Utjecaj vremena klimatizacije

na krutost nekih premazanih kartona, Zbornik radova s 13. znanstveno-stručnog

simpozija Intergrafika '94, Acta Graphica d.o.o. i Grafički fakultet

Sveučilišta u Zagrebu, Zagreb 1994., 60-68.