The 14th INTERNATIONAL DAAAM

SYMPOSIUM “Intelligent Manufacturing & Automation: Focus on Reconstruction

and Development”, 22-25th October 2003

OPTICAL COMPARISON OF REPRODUCTION

IN THE CLOSED GRAPHIC SYSTEMS

Mahovic, S.; Mandic, L.; Agic, D. & Gojo, M.

Abstract: Modernization of the graphic

production caused the appearance of different input and output units

in the systems of graphic reproduction. Each of them has the same

goal to obtain the reproduction true to original reproduction. Different

proofing systems are used today for quality control and they play

important role in communication between the client and the printer.

They are used mostly as a kind of “contract” by which the ordering

party accepts and permits the printing of products. From these reasons

color management in each particular system as well as its standardizing

is necessary.

Key words: ink jet proof, analogue proofing system,

CTP system,

print quality, colour management.

1. INTRODUCTION

Contemporary input and output devices for graphic reproduction

of an image comprise the computer with the adequate program support

as the input unit. Color printers, digital and conventional printing

machines are used as the output units. During the image information

transfer onto the corresponding output, changes in color reproduction

are possible, because of different working principle of the device

(Agic et al., 1999). Before the long run reproduction, as well as

shorter ones with great quality demands, proofs are produced. They

enable the control of colour and text reproduction and eventual error

corrections before the printing process. In dependence on the proofing

device impressions are obtained with determined deviations in colorimetric

characteristics of inks, from the original and offset printing (Mandic

et al., 2001).

This paper tries to determine which proofing device gives reproductions

true to offset prints. The device, giving better reproductions, could

be used for more secure impression control and as the evidence of

the correct reproduction. Computer generated original is reproduced

on different proofing devices and in the offset technique with Computer

to Plate (CTP) system for printing form production. Densitometric

and spectrophotometric measurements determine the deviation of the

proofs from the realized reproduction in offset and try to estimate

which of the systems is more adequate and more appropriate for the

realization of the defined demands in the reproduction quality.

The proofing device based on ink jet technology and analogue proofing

device are used in investigation. The proofing devices based on ink

jet technology enable direct production of proofs from the computer.

Ink jet devices enable the ink transfer onto the paper by means of

nozzles. The system ‘drop on demand’ defines the ink droplet by means

of the so-called piezo printing heads. The output information deforms

the piezo ceramics, which squeezes the ink from the printing heads.

The nozzles are very thin and closely concentrated. The ink dries

very quickly on the paper so there are no essential changes on the

reproductions. Analogue proofing device enables the obtaining colour

reproduction of continuous tone by screening simulation. The film

separations (CMYK) are used foils with photosensitive diazo pigments

and impressions are produced on the polyethylene substrate. Copying

through the film (each film separation separately), the disintegration

of the exposed parts of the diazo layers appear. Non exposed parts

stay on the substrate and the exposed parts are physically removed

together with the foil. The obtained proofs are compared with the

reproduction in offset. Printing forms for offset are produced directly

from the computer by CTP system for plate production. The used systems

are optimally adjusted according to the manufacturer specification.

The measuring results are presented in the diagrams with the reference

and measured values for surface coverage in the systems CIE*a*b* for

colour gamut (Wyszecki, Stiles 1982) and L*Cab* system for lightness

and chroma determination (Hunt, 1991). The proofing system, which

is better for the colour control of the original, is determined from

the obtained values. The proof is determined, which will ensure the

ordered that the colours from the proof will be reproduced in offset.

Visual comparison of the samples is also done.

2. EXPERIMENTAL

The original contains the wedge with the patches of 10, 20,

30, 40, 50, 60, 70, 80, 90, 100% coverage for 155 l/inch. The proofs

were made in ink jet technology on Epson Stylus Pro 5000 (proof A).

Analogue proof device Agfa Printon CDL 1020 R (proof B) was also used.

The same original was reproduced in offset.

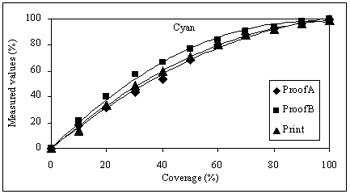

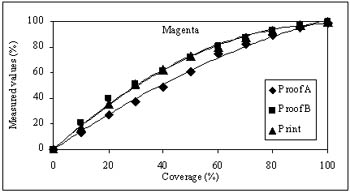

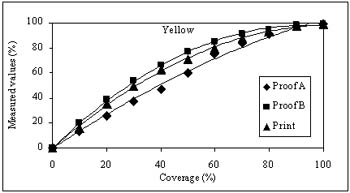

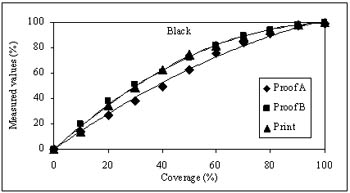

Viptronic 2000 (D65/10o) densitometer was used for measuring surface

coverage on wedge patches in cyan, magenta yellow and black. These

relations are presented in fig. 1, 2, 3, 4.

Fig. 1. Dependence of the measured and reference

values.

Fig. 2. Dependence of the measured and reference

values.

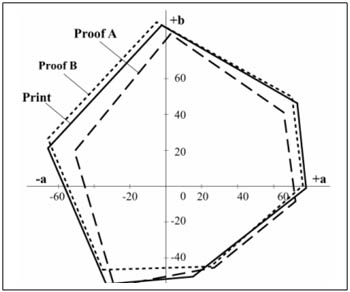

By spectrophotometric measurements on the instrument Datacolor CS3

(D65/10o) and by transformation equations the values L*a*b*, for the

presentation in CIEL*a*b* colour space were obtained (fig. 5). In

L*Cab* system the differences in lightness and chroma of samples were

presented (fig. 6).

Fig. 3. Dependence of the measured and reference

values.

Fig. 4. Dependence of the measured and reference values.

Fig. 5. Colour gamut in CIEL*a*b*diagram.

3. RESULTS AND DISCUSSION

Greater deviation of the proofing device on ink jet technology

principle is visible in figures 1, 2, 3, 4 (proof A). The deviation

is visible mostly on middle tone values on all the colours. The deviations

from the reproduction in offset, on analogue proofing device (proof

B) are very small. The greatest dot gain on offset prints is between

50% and 60% surface coverage. This is the consequence of the mechanical

and optical changes of the screen elements on the printing substrate

(Nilsson et al., 1997).

From CIEL*a*b* colour space it is visible that the proof based on

ink jet technology has considerably smaller colour gamut which can

be presented and it deviates essentially from the reproduction in

offset. Colour gamut is decreased in red, yellow and green area. Because

of that prints obtained by ink jet, do not give satisfactory data

about the colour control. In diagram L*Cab* it is visible that Agfa

proof (proof B) has greater lightness on the places C, M, Y than Epson

(proof A) and offset one. On the places Y the deviation in tone is

visible as well as in CIEL*a*b* colour space.

Fig. 6. Relation of lightness

and chroma in L*Cab* diagram.

It is visible from the obtained results that the analogue proofing

device (proof B) gives reproduction more alike the ones from offset

(smaller deviations). This is the consequence of working principle

of the device, which uses the colour separations of the original on

films to produce proofs.

4. CONCLUSION

The control of colour and text is necessary before the beginning of

long run. The proofing devices enable prevention of great waste quantities

and unnecessary costs of wrong reproduction. Changes in lightness

and chroma among the proofs and offset prints are visible. Ink jet

proofs give somewhat weaker reproduction in relation to the analogue

ones. This is the consequence of different ink application on the

substrate, which does not exclude today’s broad usage of these devices

for reproduction control. Changes in dark tones are visible by visual

evaluation on both proofing devices in relation to the offset. The

prints have decreased contrasts and weaker reproduction of the details

especially on the dark tones on ink jet printer.

In this closed graphic system, ink jet proofing system is used for

imposition control of graphic layout and analog proofing system for

image quality control. By involving CTP system in reproduction, there

is no request for further usage of films. That is the reason why ink

jet proofing system must take over the control of image reproduction

also. This is possible only by using colour management system with

weekly calibration of colour devices.

5. REFERENCES

Agic, D.; Mandic, L. & Gojo, M. (1999). Influence

of Some

Parameters on the Change of Printing Elements Dimension, Proceedings

of 10th International Daaam Symposium, Katalinic, B., pp. 5-6, ISBN

3-901509-10-0, Vienna, October 1999, DAAAM International Vienna, Austria

Hunt R. W. G. (1991). Measuring Colour, Ellis Horwood Limited, ISBN

0-13-567686-X, England

Mandic L.; Agic D. & Ziljak V. (2001). Differences in Colour Reproduction

in Closed Systems and through Colour Management Calibrated Device,

Proceedings of IARIGAI, ISBN 0-88362-401-X, Montreal, September 2001,

Canada

Nilsson, C.M.; Malmqvist, L.; Busk, H. & Kristiansson, P.

(1997). Optical Enhancement of Closely Positioned Screen Dots, Proceedings

of TAGA, Taga office, pp. 11-21, ISBN 14623-5604, Rochester, NY, 1997,

USA

Wyszecki G., Stiles W.S. (1982). Color Science: Concepts and Methods,

Quantitative Data and Formulae-2nd Edition, John Wiley & Sons,

ISBN 0-471-02106-7, Canada