FINISHING EFECTS IN DIGITAL PRINTING – CLEAR TONER

Brekalo S.

1 Elektrostrojarska škola Varaždin, Croatia

Abstract

Digital printing notes exponential growth lately. Investments in development of digital printing machines produced first digital printing machine with five colours able to make short runs with clear toner. With this toner it is possible to produce, for the first time in history, different finishing effects in digital printing.

At Drupa 08 Canon announced new compact colour printer, the ImagePress C1+, which proved to be a surprise success (http://www.drupa.com). This machine has a fifth colour, clear toner which can be used to apply an overall coating to control gloss levels as well as selective security features, spot varnishes and metallic effects. Spot coatings and metallic effects can be applied while printing or it can be used as a coater for pre-printed sheets.

This novelty changes the definition of the digital print today. Today also other digital printing machines manufacturers offer the same toner in their production workflows.

This paper deals with the commercial use of the machine, and also its advantages and shortcomings.

Key words: digital printing, clear toner, security, metallic effects, spot varnish, coating

1. INTRODUCTION

It’s been almost 15 years since the introduction of what we think of as the digital press, a PostScript-based, full-colour, completely electronic digital output device. More than half of all graphic arts firms now offer some kind of digital printing in-house, whether colour or B&W (The Industry Measure IM Printing #25, Spring 2007). Consequently, the tipping point between when to use offset and when to use digital has become even more critical than in years past, since it faces more firms on a daily basis.

Innovations in digital printing constantly change the equation between offset and digital, especially when they give new technologies that can be implemented only on digital presses making the difference between offset and digital even wider.

One of the innovations is Clear toner which opens the door to new possibilities in graphic arts production and design. Clear toner can add value which can not be compared to offset and it broadens the horizons of digital printing.

2. DISCUSSION

2.1. DIGITAL OR OFFSET?

When we ask the question, "offset or digital?" there are three primary factors to consider:

- First, the technical aspects of each press, including format size, run length, print quality requirements, need for spot or brand colours, and special finishing needs

- Second, the applications to be produced, whether static or 1:1/variable data

- And finally, the total job cost, including prepress and bindery.

Back in the mid-1990s, when digital printing first gained widespread acceptance, the primary goal of digital printing was to win short-run jobs from offset. From this perspective, the tipping point was merely a number—a run length at which the per-piece cost of digital exceeded the per-piece cost of offset.

Today, however, we realize how simplistic those early analyses were. Moreover, the digital machines, the workflows, the applications, and customer expectations and needs have changed so radically that any generic discussion about offset versus digital has become impossible—if it ever really were possible.

The quality gap between digital and offset is narrowing. According to The Industry Measure Design & Production #22, Summer 2006, 82 percent of creatives with an opinion on this issue are now either "satisfied" or "very satisfied" with the image quality from digital presses.

Although digital has come a long way since the first Indigo E-Print 1000 was introduced in 1993, there are still limitations. Digital presses cannot run metallics, although some approximate them better than others, and while the range of substrates is broadening, it is still not as broad as offset. Certain finishing techniques, such as embossing, also cannot be used on digital press output. The largest production digital presses are 50x35 cm—so before the "offset versus digital" question becomes relevant, the job must fit within this format. If the answer is yes, then issues such as cost-per-piece, print quality, colour fidelity for brand or spot colours, and the ability to accommodate any special finishing requirements play a critical role. Then there is the issue of application. If you want true, on-the-fly personalization, offset won’t enter the equation. On a job-to-job basis, the deciding factor is the quality required by the customer.

Today with the development of clear toner for jobs that require it, we can instantly decide. Effects with clear toner can not compare to effects with clear varnish in offset printing. There is a whole new dimension of possibilities that can be derived from the use of clear toner. The clear toner enables designers and graphic arts professionals to expand their capabilities and offer a wider array of innovative printing solutions.

We can generally say that digital print is the right choice for jobs needing:

- Variable data (personalization)

- Web-to-print

- Shorter preparation times

- Identical copies with no colour shift

- Less waste

- Less cost for short runs

- Benefits of special effects from clear toner and other special digital printing options

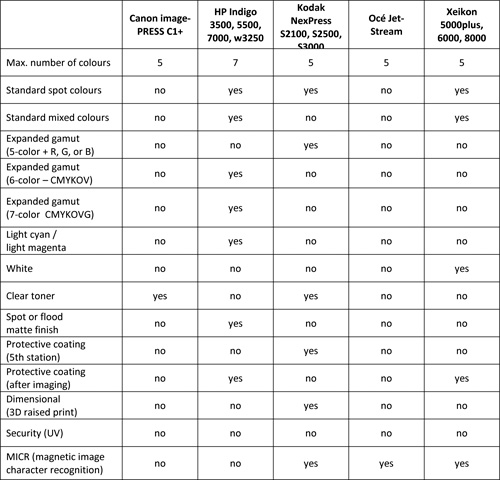

Today we have machines with more than one colour which can give more different effects broadening possibilities of digital machines and their use (see Table 1.).

Table 1. Currently available machines with more than one colour

2.2. CLEAR TONER

Clear toner gives new capabilities and enhancements to printed output such as spot, flood, watermarks and metallic effects. It is different from other toner technologies as it is transparent and due to its nature, the clear toner can give new effects that other printers cannot achieve. Clear toner takes production capabilities into another dimension. The added feature of clear toner offers exciting new possibilities for design and it expands what is posible to offer customers in the printing market.

2.3. CLEAR TONER EFFECTS

Clear toner can create watermarks to enhance security. Watermark printed by Clear toner is useful for document Security (Certification of original) or for decoration. If making a copy of output printed with a Clear Watermark, the copy of the watermark vanishes. The Clear toner doesn’t appear on the copied paper and it cannot be copied by a scanner. This effect is available for tickets, voucher promotions, confidential reports and office documents needed to certify the original. The watermark provides excellent, cost effective security against forgery and replication.

Fig. 1. Office Document |

Fig. 2. Ticket |

Metallic effect is created by adding a CMYK light halftone colour to the Clear toner, which appears brighter than that of the output from just the CMYK light colours. The Metallic effect is limited to printing clear on low density areas of the media. If clear toner is printed with solid colour areas, this effect doesn’t work at all.

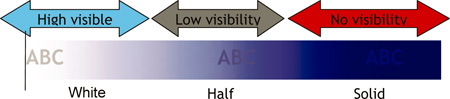

Fig. 3. Clear toner visibility in metallic effect on different densities of CMYK colours

It is used to add value to cards, collateral pieces and other printed materials, for metallic characters or decoration.

Fig. 5. Metallic character |

Fig. 6. Metalic decoration |

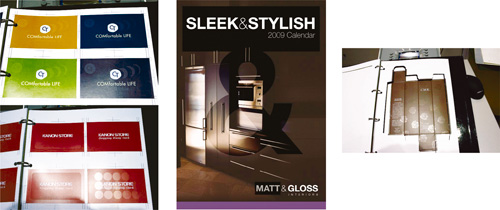

Clear toner allows spot matt/gloss coating to create elegant designs. When applied to a pre-printed CMYK page it will create matt or glossy effects, depending on the media used (paper sort). Clear toner will flatten the gloss of the paper when applied on glossy paper and it will look glossy when applied to matt paper.

Printing clear toner on high gloss areas gives a matt effect and without clear toner, the area displays a gloss effect. This gloss difference (Matt or Glossy) can emphasize particular areas on printed output. So the image area without clear toner looks glossier compared to the other areas of the printed output with clear toner. The difference between the gloss and matt creates areas that really stand out.

Fig. 7. Business card |

Fig. 8. Leaflet |

Fig. 9. Package |

Flood Matt coating can cover a large area of printed output as well as adding protection to the printed material from scratching, smearing, rubbing and the minor effects of water. The clear toner applied in this case protects more effectively than print with just standalone CMYK toner.

2.4. DISADVANTAGES IN THE USE OF CLEAR TONER

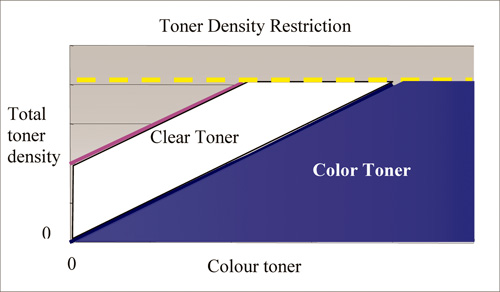

Machines using clear toner have Toner density restriction. Toner density restriction makes it hard to get a clear toner effect to stand out in one pas through the machine on solid arias. In the case of the 1-Pass process, there is less effect of clear toner on solid colours due to a higher density of toner on the page. If the colour is lighter or has less density on the page, then the application of clear toner has a more apparent effect i.e. Metallic effect.

Fig. 10. Toner density restriction

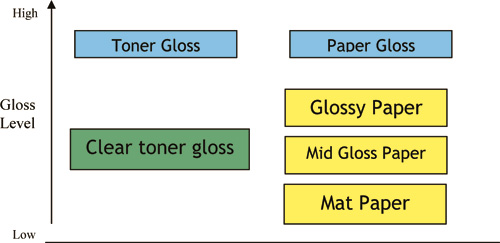

Not visible on all sorts of paper. Clear toner and CMYK toner have the same Gloss levels. To achieve a Glossier effect with clear toner, you must use Matt or plain paper. When using glossy paper, gloss of the paper and clear toner are at the same level, and the effect of the toner can hardly be seen.

Fig. 11. Toner gloss on different sorts of paper

Application of clear toner to pre- printed image sometimes causes problems in printing.The 2-pass process may affect the image of pre-printed paper. This means that some pre-printed images may be affected by the heat from the fixing unit. Also, printing clear toner on some specific images may cause a registration challenge.

Extremely high gloss can not be achieved due to the restrictions in toner gloss.

2.5. ADVANTAGES IN THE USE OF CLEAR TONER

Low price of special effects- Clear toner can be used for small volume printing of special effects with lower price

Low cost proofs- Clear toner gives possibility of making low cost proofs for higher volume printing with same effects

Expanding possibilities- of graphic design and for new jobs for digital print

With clear toner it is possible to make Variable data and short run printing with added value.

Clear toner gives High security for documents and printed materials from forgery and violation.

3. CONCLUSION

The unique clear toner feature introduces to the creative market a visual texture treatment that expands design capabilities. From subtle delicate suggestions to a bold creative image, this affect impacts the message to the market. Additionally, the new clear toner feature makes it an appealing option for corporate environments that are looking to add security features such as watermarks to their documents, without distracting or altering the design elements. Development of toners in digital printing is a way to make digital prints stand out and broaden its use and market.+

4. REFERENCES

Gretchen A. Peck (2007.), Ink & Toner: Key to a Better Digital Print, Digital Publishing Solutions, availabe from: http://www.citrads.com/digitalprinting.php#

Accessed: 10.01.2009.

Harald Johnson (2005.), Mastering Digital Printing, Second Edition, Thomson Course Technology PTR

Heidi Tolliver-Nigro (2007.), Digital Offset - Defining the Tipping Point, Digital Publishing Solutions, availabe from: http://www.citrads.com/digitalprinting.php#

Accessed: 10.01.2009.

Image Press C1+, Product Introduction Document Version 2 (2008.), Canon Europe Ltd PSM Planning,

Kipphan H. (2001.), handbook of Print Media, Springer- Verlag, Berlin

The Industry Measure IM Printing #25, Spring 2007

The Industry Measure Design & Production #22, Summer 2006

Messe Düsseldorf (2008.), Canon's a 'clear' winner, availabe from: http://www.drupa.com/cipp/md_drupa/custom/pub/content,lang,2/oid,13970/ticket,g_u_e_s_t/local_lang,2/~/

Canon_s_a_clear_winner.html

Accessed: 15.01.2009.