Keywords : Networking,Printing,Workflow,XML,

Internet, JDF

1 Introduction

The romantic times of the printing industry and closed guild behaviour has

remained something we know about only on basis of anecdotes. Electronic publishing

has been accepted everywhere in the printing industry and has become part

of a person's general education. With the help of informatic technology there

is an increase of a printed product's value and the product is undergoing

many mutations, becoming more interesting, unique, individual. Basic e-definitions

of printing are redefined: the original copy, color, media on which a product

is printed on, the bearers of printed form. The news in the printing industry

means "informatic integration" of all printing and publishing matters, those

of actual graphic product production, including Internet technology. Printing

works have not been using databases up to the time electronic newspaper editions

were implemented, a parralel campaign of all the publishers. Appearance of

electronic book and magazine editions is still in the phase of copying graphic

layout of a printed book in PDF(*) and HTML formatting levels. The most valuable

points such as links with other publishing programs and browsers are still

missing. The so-called linking is on the level of browsing within the same

publication or finally as a supplement to literature.General integration within

printing is implementd from a totally technical point of view. The standartization

of linking printing machines, the production process and process automation

is being organized. Machine producers have enforced this gathering around

the CIP4 movement in order to make a considerable improvement in the level

of machine exploiting during the printing process. A new informatic language

called XML has been created in the meantime, as well as many of its sattelites,

such as XSL and DOM. Each field of business had to make its own expert dictionary

and rules for use in order to understand the machines, relations in relation

databases, inside and outside information flow. The printing language called

JDF was created and is undergoing a major development process, still far from

standards, and is the most important point in the graphic industry of today.

This may be comprehended from the fact that JDF is in the titles of all subjects

on development of printing. The elements in the printing industry development

are set by the users accepting knowledge and the choice to introduce modern

technology based on the XML communication system. Printing works will go through

internal reorganization beginning with cretaing digital standards for all

activities, business deals, machine de scriptions, material descriptions.

This cannot be forced as a ready-made solution, but will be the result of

joint efforts of computer experts, printers and printing engineers. A standard

digital system must be implemented so as to move closer to production planning

standardization, offer standartization, job order standardization, and optimal

use of new printing technologies.

Relation databases are linked through methods of "natural"

XML databases organization in all business fields, thus in the printing industry

as well. In order to enable communication between various participants in

printing business, and most of all this applies to publishers, a native digital

printing language must be created. At a first glance XML is extremely simple

and because of this it has undergone a wave of mass exploting, by a vast number

of new programmers and an infinitive number of solutions have been offered.

However, it is high time that a graphic business center is organized in Croatia

as well, which would elaborate a dictionary of digital printing activities

also covering segments and links. Due to the fact that a specific technical

dictionary is developed for each machine in a printing works describing variables,

work processes, communication hierarchy, a new chapter is a language for translating

all of this in order to understand different elements comprised in processses

such as planning, control, production technology and many many others. The

world center or the CIP consortium has this job; to coordinate the global

printing industry language and native printing industry communication languages,

with the goal being general standartization The future of the technological

segment is seen in applying hybrid printing. All by itself this word would

not mean anything important if there had not been the necessary integration

of digital and conventional publishing giving optimal results in many areas.

Digital printing has offered sequence printing, i.e a printed form is formed

in real printing time, enabling the printing of page after page and is leading

to the possibilities of each printed product being individualized. As computer

speed is developing, the RIP process will be carried out before applying ink

to substrate. The development of many modern printing areas has been made

possible by these digital means of controlling the actual printing process.Individualization

is, therefore, forcing itself as a really possible marketing novice with new

solutions in design, but most important: in production planning. CIP4 will

flourish here. The printing machine as a central point of action in the printing

process will not only perform sequence printing of the same product.

But also a combined printing of various products in a continual printing process.

Linking of machines for arranging the products, bending, cutting and binding

in the CIP3 system enables a multi-pole applying of the printing work without

fear that everything would be mixed up. The change of material at the process

entering point is programmed for i.e. a whole day digital production plan.

In simple terms, adjusting the machines for bending, cutting and other postpress

jobs is controlled on basis of information and data travelling together with

the printed sheet. Thoughts on printing simultaneously various printed matter

parts is the beginning of accepting CIP4 standards. This paper sets forth

the question whether human engagement is necessary. The printing works requires

fresh knowledge, new skills, urgent retraining. The education system is undergoing

adaptation and preparing to educate experts for the oncoming printing industry

transformations.

2. Digital networking of printing

The entire field of printing science and industry function as an electronic

business association. The turning point is the acceptance of Internet and

its power. The Internet is not only a pile of information but is also a vast

market, and a new way of market opening. Fundamental changes in the printing

industry affect production cycles, price structure, industrial services. It

is a matter of significance that a job can be executed through the net. The

job may comprise of the following: promotion, negotiations, tenders, decision

making, ordering, carrying out digital transactions, payment, delivery planning.

It is necessary to make the first step, and be aware of the need of business

reorganization. Informatic infrastructure has proven to be effective in the

printing industry from the beginning of this century.

2.1. Software and hardware in printing industry

The printing industry has accepted network automationand the Internet and

is undergoing continuous transformation. Nothing remains the same. The printing

business is preparing for changes in all its segments depending on the fact

how and to what extent certain plants are envolved in digital control. Terms

like: soft printing environment, hard printing environment, a mixed printing

environment and a supersoft printing environment would be applied. The last

one is related to the Internet, the Web, database, computer memory) workflow

control and printing works control through virtual simmulation of production.

Soft plants like for instance those for prepress will be altered completely

every two years. Communications - the supersoft printing technology - will

be altered each year. The harder printing structure depends directly on the

development of computer integration with the printing industry and depends

most of all on implementing standartization in printing. It seemed that postpress,

let us lable it as a mixed printing environment, will not be altered at this

exponential rate. The wish to link all workflows into a singlče informatic

unit, has made the postpress machine producers develop many new patents. Their

derivates are multiplying, spreading and duplicating every 18 months, at the

speed of computer development, because automation is implemented here.

2.2. The correlation between computer development and the advances

in printing

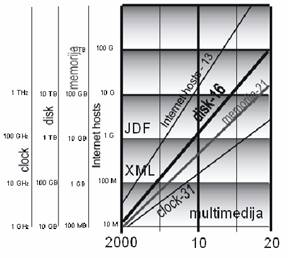

In previous papers on the correlation between the situation of the computer

technique and prepress and the introduction of automation into conventional

printing, it has been proven that discussion is possible only in the light

of exponential development. Digital printing has begun from scratch - printers

that have undergone general alterations in the eighties by implementing the

PostScript, the language having the pretension to become the printing industry

standard. This paper will try to forecast what will happen in the next fifteen

years, a period during which we all will be active users of printed products,

the printing technique and training in the printing industry.

If science, discoveries and patents on which the listed variables are based

upon have been behaving in such a determined exponential manner during the

past twenty years, one must believe that the same parameters will remain in

the time to come. The future development is undergoing discussion with the

following question being stressed: in how many months shall we be facing a

value double in size for each variable? Doubling occurs in 21 months when

the computer memory is monitored, 27 months when computer speed is surveyed,

16 months for the discs and only 13 months for Web-Internet application (www.pira.co.uk

"Five YearTechnology Forecast of Printing and Publishing" - Pira International,

data is updated with the Network Wizard www.nw.com "Internet domain survey"

www.isc.org/ds/host-count-history.html). The following relations are suggested

here (see left column): rasta onih varijabli koje bi trebale in which for

the X = 0 variable Y gives the value of the number of Web-host computers in

the world in the year 2000. The relation is data approximization from the

year 1981 (X = -19) till 2002 (X = 2). On basis of this we have the result

that the Web system is multiplying by ten times in the space of three and

a half years. If we were to place the possible changes and implementation

of the Internet in the printing industry within the same relation, the conclusion

is that there should be speedy preparations for the grahics system reorganization.

If three and a half years is the minimum time necessary to educate a graphics

engineer, then we are facing the task to interfere in a major way as to the

manner graphics technology is studied.

On basis of studying many reports on the future of computer

science systems in the printing industry, correlations are established in

respect to computer machine development. Studies are aiming at helping in

business strategy planning in a responsible and safe manner. (Confidently

accurately. The Future of Print 2, ISBN 1 85 802 9414 , Pira International

Ltd.).

Data on many essential points determing the printing industry, the opinion

of experts and their original reports are used in creating the development

and innovation implementation scenario. Minor, mean and highly developed scenarios

for the future are set. This paper would offer some critisizm and reservedness

in respect to such reports. If observed from contemporary standings, articles

and papers dating a few years back were more than modest. The forecasts for

digital printing patents development had given twice the time lapse in which

this would occur. XML (1) technology had not been stressed anywhere, nor the

new language in the printing idustry JDF (2). It is similar as to the standing

of the most competant architects of the printing industry development scenario.

In a few words, the general opinion is that the future will be developing

in a linear and not an exponential manner. We have here the growth relations

of those variables that should be the fundamental basis for reconsidering

many of the printing industry parameters: the Internet, computer memory, external

storage - discs, computer speed.

This is a bold prognosis based on the area of dataextrapolation 20 years back

in time. Maybe it is incredible,but activities in the printing industry are

in full correlation with computer development. Figures should be considered

in logarithmic transformation. Lead typesetting has being going until twenty

years back, whereas computer implementation into this field began only with

the photographic matter in the 20th century's seventies. The equipment was

extremely expensive and only the newspaper industry could be the leading field

of business for applying all new computer science technologies. Computer power

has enabled only text processing. Digital scanners have been implemented gradually

into photoreproduction departments and full exchange of previous technologies

has become a practice only ten years ago. People were waiting for the speed

of computer image processing and access availability to corresponding memories

to become competetive with the analogue and digital techniques. In theory

many applications have been developed earlier, while the good results with

computer graphics functioned on the main forms with computers that could not

be transferred to printing plants. All such things as computer annimation,

multimedia, sound, has been shown as far back as thirty years ago, but was

at that time a matter of art and exclusive application. We have been waiting

for the "mammoth computers" of those times to become personal computers for

general use, available to all, without being a threat to the standard of living.

Nothing is definite in the printing industry but nothing will be as it has

been. The development of computer science continues and according to all the

coefficients this is taking place exponentially. It will be seen in opening

of new transformation and phases of change in the printing industry: the Internet,

digital image transfer, digital control of production and planning; the path

towards communication technology is set in order to fully integrate publishers,

customers, printing processes, paper production, sales. During symposiums

held worldwide there are often polemics on how there will be no exponential

computer science development in future, and therefore - no drastic changes

in the printing production. This is generally the viewpoint of the older generations,

whereas the young generations are consciously preparing for new alterations.

The most important subject is the JDF as the printing production language,

as one of the XML technology schemes, as something that is integrated into

the chain, beginning from the publisher all theway to the customer and digital

and conventional literature.

3. Languages of the 21st century printing

New lines of thought, new programmers and new types of jobs are organized

at the same speed that hardware is developing. The extraordinary HTML that

has promoted the Internet more than anything does not enable explosive implementation

of ideas of display on the most various media, complex transformation and

entering into various databases. The HTML's graphic design has two integrated

subjects: data source and the planned Web site. New technology bearing the

common name XML has advanced further and is based on several premises:

The First: data and data structure are separated from the

physical display programming and an edited report design. Data is described

- marked - in an understandable language, in detail, with the text being in

the mother tongue. Thus matter identification is simplified and the exploiting

by various users for various purposes is made possible. The prepress up to

printing plated production has the path towards the electronic edition, searching,

rearrangement of page layout, adaptation of the page layout to the end user's

needs. XML's conception of data being separated from the display simplifies

the matter of the "digital kiosk", remote printing, printing on basis of content

choice, individualized printing.

The Second: Through the Internet technology one enters simultaneously

into various databases, various data files and various sources, thus forming

a unique XML structure. This is where native data bases are begun for a typical

XML structure. The matter of software and hardware compatibility are avoided.

Independence as to the computer type and operative system is at maximum and

very stressed. Databases are entered from anyplace, anytime.

The Third: Instrumental data are manipulated together with

other data from databases, as for instance production planning and control

data. Such data circulation is interactive production control; machine regime

altering, work process parameter adjustment for omptimizing purposes. Internet

technology enables remote data reading of parameters on various device for

the purpose of informing in real time.

The Fourth: A dictionary is the the beginning of standardsetting.

XML technology requires organization of a communication expert dictionary.

The printing industry has begun the designing of a JDF industrial standard

language for its own purpose. On basis of a print production dictionary, a

path for drawing together production organizing methods has been set, as well

as for calculation, warehouse control, use of all the machines in a printing

works. When applied in printing jobs, Internet technology must rely on a language

that is independent from the machine producer and the end user in the printing

works. A dictionary is the beginning of serious cooperation between the competitors

with the common goal to improve all the parameters of the print production.

Integration through a new printing dictionary is becoming reality. The position

of a native tongue is stressed and this would also be a warning that fundamental

education is necessary in respect to new standards announced through JDF and

CIP4.

3.1. Data exchange between machines

JDF comprises the complete printing job of publishing, beginning from the

author, design and ending with the placement through the network digital system

under XML technology. There is no mention of conventional printing, digital

printing, alternative or hybrid printing. Everything is united into general

printing that has a goal to produce competitive graphic products. The JDF

system covers the complete production process. Let's define the workflow as

automation of job processes in whole or in segments, during which documents,

information or jobs are passed on from one participant to the other for the

following job. The use of digital relation databases and XML technology is

understood as those relative for the JDF environment. A participator is understood

to be any resource, man as well as machine. Workflow tools enable automation

of controlling either wholes or segments of the process, an advanced carrying

out of tasks according to known rules defined in advance.

3.2. Databases and Digital Printing

A computer science based society relies on databases, science bases, eLearning,

the Internet. Digital printing followed by the whole printing industry has

found its area of spreading in such an environment. Informatization must comprise

individuality as well: databases on potential customers grouped in respect

to their tastes, needs, income scale. Databases on new, future and old products.

Databases on printing technologies and material. Databases on designer solutions

and the designers themselves. Databases on companies, their logos, favourite

products, success reports. Databases on production standards, prices, exploitation

conditions, the borderlins for operation of each machine in the printing industry.

All this is data in the relative ba ses that are being the source for making

prints with individualized characteristics. This is where the proposal for

implementing XML technology into the printing business is set: databases and

digital printing. Communication: only through XML technology, whether we are

in the printing works grounds or connecting with the outside world as well.

Digital printing is the incubator for a new and serious world of printing

technology that is constantly spreading. Furthermore, networked printing works

is the basis for discussion about the changes taking place in the printing

industry. Network production is the main subject for a modern production organization

and it affects investments, education, management. A network is not only an

independent area in the printing industry but through databases it integrates

a new printing industry life. What is flowing through a network? What kind

of data? Is it only information printed on paper or is it information on production

technology and production control. Printers in a printing works did not deal

with computers previously, and now such technology will become the center

of their thoughts. XML technology enables information to be taken out of databases

to diverse media and one such media is the printed product. XML may be understood

only when one has performed implementation, programming and used tools for

databases organization. In order to connect graphic prepress and XML technology

it is necessary to apply XSL, XSL-TO procedures and to prepare graphic displays

for various printing machines. XML does not require "a language in codes and

abbreviations" understandable only to the programmer who becomes incompetent

with such technology as well after a certain period of time. In first applications,

especially in machine data manipulation, an English language basis is forced.

As XML variablesmay be textual description, it is recommended to use native

languages for marking. There will be wider and stronger motivation because

of the more simple understanding of contents.

The first applications are textual XML native databases with XSL exits, data

content change and printout. XML is an extremely simple recording, understandable,

flexible and modular. The next is connecting with relative bases (MS SQL server,

Access, Informix, Oracle).

Programmers tend to make a turn towards using Java, C++

and JavaScript languages. It is suggested to use these languages in the calculation

area and data flow control.

3.3. Text and image graphic display

The prepress of today has problems with conversion of text on various computer

platforms. The fonts and communication programs for production of plates are

not adjusted and this problem is getting more and more prominent as computer

techniques are developing. The development in the direction of contemporary

and up-to-date programs for page layout has come to a stop because the complete

prepress is turning towards XML technologies. XML programming plays an important

role in the field of graphic products. XSLT (Extensible Stylesheet Transformations)

is the most important central type of technology for processing and remodelling

of XML ( eXtensible Markup Language) in prepress. Originally it was designed

for forming of dynamic display of XML data pages. Now it can be discussed

as a general purpose tool for translation and reorganization of documents

of the same contents, and generating multiple results as for instance those

for HTML, WAP and SVG forms. XSLT is the basis for display of many XML solutions.

As a standard it sets the way of transforming XML documents into other XML

formats, HTML and many other formats that we meet with Web technology. XSLT

transforms the contents of an XML reading roughly generated in prepress from

simple tabular displays up to complex sorting out, connecting and dynamic

selecting.

With XML technology it is expected that the data is described, saved and transported

through the Internet and the Web.The independence of XML data is the beginning

of real communication between printers, printing works and publishers, publishers

and work groups that are preparing images and texts, printers and image bases.

This independence applies to printouts whether on their way to the CtP or

for digital printing on some other location. The adaptation of machines to

national requirements becomes unimportant, as each display, i.e. print-out

is programmed independent of the original source.

XML solutions offer a new way of communication using various operation systems

and computers. Due to the fact that diverse systems are integrated with XML

technology more time is necessary for this project to be implemented because

this technology does not give fast results.

In order to implement such a general transformation into graphic prepress

the following is necessary:

- designing of special DTD tools production adapted to the graphic design

- a plan for converting the exsisting forms for organizing bases of ready

layouts of graphic

- products into the XML standard data system;

- a project for browsers, filters, selectors and structures to display texts

made in times of analog printing practice.

4. New specializing in the print production

There is specializing of some new fields in print production and this should

be considered not only in respect the said area, but also in respect to the

education system. The following work groups are suggested according to their

general characteristics:

1. Organization of database structure for the print production. Development

of forms for data input with the corresponding schemes. The development of

personal "private" XML languages for personal activities.

2. The development of a mother tongue dictionary for the printing and publishing

applicable in XML technology. Translator development for other mother tongues

and other communication standards in graphic arts.

3. Interface development between XML and relation databases: MS SQL server,

Oracle, Access, Informix, as there is need to use data from information systems

that have been in use in this country. Connecting of data from the warehouse

and financial business operations with the job order. Development of XML solutions

with the goal being to substitute the existing relative databases.

4. The development of XSL, XSLT, XSL FO solutions for data display for the

display monitor, PostScript, PDF.

5. XML scheme development for instrumentation specific for machines in the

printing plant. Study of JDF characteristics, application and advice on new

machines.

6. Application of XML and relative databases for graphic product production

calculations, tender making for the end user and job order making.

7. Organizing picture albums, logotypes, layouts.

Organizing databases on printing techniques, material (paper,

inks, toners, glues) with the corresponding work speed standards, prices and

time necessary for individual job phases.

The reason for not having until now the application and designing of information

systems in printing processes that comprise the actual production is because

of the total lack of production standards. Each printing works developed individually

for it's own market. This is illustrated best by the situation in getting

a tender for a concrete job. The prices may vary from a relative range of

1 to 4, although the production technology may be almost identical, as well

as the material and the staff having identical qualifications. The standards

on calculation are most often in the hands of a single person, in his notes

that are kept as a top business secret. The digital system of standards opens

the path towards standardization. Prepress may be described with some twenty

tables, Printing with the number of printing machines. The final or postpress

jobs are described with several hundred complex relative structures even when

a small printing works is in question. If this enormous number of standards

is taken into account it is a wonder that a bigger difference has not appeared

in planning the cost of a product. By following up and analyzing former successful

jobs a "ready-made method" was developed resulting in the specialization of

each individual printing works. Non-existence of printed standards and not

using internal memos brings damage even to successful printing works. The

following work groups: have been organized within the WbPoskok project printing

production:

. Digital standards development for the prepress;

. Digital standards development for the press;

. Digital standards development for the postpress.

The standards are in the MS-SQL server and are available through developed

DOM procedures. The calculators are in XML technology with JavaScript program

support.

The first question to be posed when XML technology is planned to be applied

for calculation making jobs is "At what speed are results obtained?". The

speed is instantaneous but the more important question would be "Are the same

standards really always applied?"

Improvements:

1. All the performed calculations are saved permanently.

Thus each calculation may be later used as the initial pattern for making

a new offer.

2. The accepted offer is the basis for production planning and making the

job order. Standards have the possibility of "hidden values" and this applies

firstly to prices that are the data for concrete market activities.

3. The job order is cummulative with an alarm on the production phase state

it applies to.

4. The database is linked with the data in the warehouse, the shipping department

and those engaged in forming of commercial and financial reports that are

usually successfully done with the help of conventional methods. The open

and available to all data may be found at: http://webposkok.fotosoft.hr/kalkulacija.

5. Conclusion

Studies on the printing industry future are most often dealing with variables

that usually do not have very significant changes as, for instance:

http://www.smartfactory.org/smart/presentations/PBeyer_DSFactory.pdf;

paper consumption, participation of ads in newspapers, the quantity of new

books, connections with new media, the rise of daily newspaper, magazine,

brochure editions. Internal changes that are taking place in the printing

industry are in respect to information flow, computer technique implementation,

including new printing techniques, and this is what changes working habits,

working places, communication between the publisher and the printer, and shortens

the time necessary to publish fresh information by using printing techniques.

The goal of JDF may be based on wishes to dramatically enhance productivity

along with workflow automation. DTP (3) has improved workflows but in the

prepress segment even now it has a uniform rise in influencing graphic production.

On the contrary, network flow implements changes in print production in a

much greater way. Things are going in a direction of total job and business

process integration. E-production - everywhere, anytime. What is expected

in the future printing?

Printing process line control is being introduced:

Prepress, press, postpress. This will take place only when interfaces are

introduced into the printing works between the machines and the computer systems.

Each machine must be described in detail through standards in various editions,

material, printing actions. The interconnections of machines are described

as the bottlenecks in production.

The success of the survival and development of printing lies in improving

business dealings through improved printing services that, for example, develop

XML based technology in the field of printing, communication, management.

We have encouraged printing works by promoting digital movements in the printing

industry as far back as the time of phototypesetting, DTP, continuing now

to XML and JDF. All of these are only the beginning of a great transformation

in the printing industry. Printing co-exsists with the electronic, so-called

ePrinting and this is will determine the future of printing industry. EPrinting

comprises the reproduction on paper directly from the computer, better known

some twenty years ago as the idea of Desk- Top Publishing. Digital printing

machines are turning into device that do not require specially trained operators.

A maximum simplicity in handling is a part of the digital business culture.

E-printing includes participants who are ready to accept the new era and the

following are comprised in this group: e-authors, e-users, e-publishers, e-designers,

e-planning dept., e-order, e-printing works, e-postpress services, e-sales,

e-archives and other participants of the e-society. All of them communicate

and exchange information through the Internet as an electronic business society.Thus

the requirements for speeding up printing time will be met, as well as reducing

production expenses of conventional publications, resulting in a web e-publication.

New relations between the users, printing works and material suppliers are

created. New sources of authors, reproduction material, expert advisors, services,

and new marketing relations are found. The customer and the producer are linked

by the Internet and knowledge. All these participants are on line. Only people

having a digital business culture will succeed in business with an e-based

printing technology.

7. References

References are cited within the text