PRINTING PROCESS SIMULATION BASED ON DATA FOR STANDARDS TAKENFROM ACTUAL PRODUCTION

Žiljak Vilko, Ivana Žiljak, Klaudio Pap, Zoran Nježić

Abstract :

The paper shows the created tools that enable a description of virtual printing machines with all the belonging parameters and material necessary for the printing process. Real-life characteristics are built into the virtual machines and the measured time periods for individual machines in the printing process. Thus the cost-efficiency order of each machine for certain types of jobs was obtained, and the digital job order system was determined.

The results obtained are the ones improving and raising production planning and control on a higher level, as well as allowing additional building-in of JDF. The set goal is to create as many production situations as possible, archive the gained results into databases, aiming at getting a complete computer science description of graphic production units and situations.

Keywords

: normative provisions, XML, simulations, printing, estimation

1 Introduction

Computer simulation of printing processes enables the research and study of the smallest workflow structures and interconnected dependencies of multi-linked variables from prepress to postpress. A field is created with an enormous number of possible solutions for preset jobs with instructions on the best choices for a certain printing works and for the given types of business management. Computer simulation means carrying out many experiments in the environment that is close to what we might consider as the best solution. It is possible to make many different versions if data generators are prepared in advance in order to initiate carrying out new experiments with algorithms. Only a base of initial data describing certain variables or algorithm data generating enables multiple simulation experiments. The actual questions might be: test a continuous edition of 10 to 50 thousand copies, for Poliman or Litoman machines, for pages from … to …, etc. regardless of the data from the concrete offer request. Many variables are given in the graphic product description comprising: printing machines for the given printing works, manpower, material, time period necessary for the completion of certain phases – all in differently defined value ranges. The “graphic space” for possible initiators of printing process simulation experiments may be through norm regulation tables or mathematically with the help of related algorithms. Simulation processes are based on printing press norms and take place twice. The first simulations are in the part where answers are given in respect to the client's offer request. This is the part where the situation in the graphic production market is taken into account, as well as the competition, and the monopoly over the product. The second phase of simulation takes place after the job is granted, i.e. after the order has been placed. Both of these simulations systems are based on production norm data, but with different goals. The working out of concrete estimates for the first as well as the second phase is vital for the printing organization administration. Computers and new programs for estimating “good production” enable the simulation of a great number of combinations and automatic search for quality situations that becoming better and better. New production paths are the goal of simulation as well as stepping away from standard behavior in making decisions that are characteristic for printing business calculation specialists.

2. Defining production entity norms

The necessity to implement digital job orders and to monitor the production process requires a detail and complete graphic production plant description. Computer science description requires real and actual values that have been acquired on basis of measuring and testing certain units. This paper describes the tools that enable norm setting and storing individual machine parameters in databases. Through XML a relation and data visualization have been determined between: the database – the user – the digital job order. Solutions are given for organizing and using of the relative and native databases with the goal being to have a final and complete operating cycle simulation. Thus a new approach to production planning is given including the following: prepress, press and postpress.

The basic condition is to provide a systematic approach to norm setting for all the elements that are part of the graphic production. It has been determined that the defining of graphic postpress requires the most thorough and most complex computer science descriptions of machines because each machine is specific in its own way in respect to the functions it performs. Description of certain postpress machines requires the setting of a functional dependence of parameters that are specific for that certain machine. There are several hundred different types of machines used in postpress. The norm setting system is based on the measured periods of time that are defined by the influence of various types of material used, edition quantity and the respective prepress prices and prices for machine/per hour use.

A database construction is based on the belonging tables definition for each single postpress machine. The database contains values needed for initial calculations and production control. These are numerical and concrete machine production norms. From each table there is an XML description created for each machine separately, with defined and described specific characteristics. On basis of given schemes it is possible to alter norm values, and to reach them. The estimated values are stored in temporary DOMs (Document Object Model) in which they “travel” for further production activities. If there is necessity, it is possible to save these values as well, not on the norm level however, but on the level of production control. Thus the link in respect to organization, production control and postpress production control level is defined.

A system describing individual graphic products is proposed for the process of setting norms for the prepress production. The descriptive parameters define the graphic design, page-break, scanning, and specific accessory jobs. The price and belonging time period are linked to each of these parameters. The categorization of norm descriptive parameters that are subject to adaptation in respect to certain prepress plants is proposed in the database.Norm setting for the printing process includes the definition of parameters describing individual printing machines. A system is proposed that stores parameters such as the number of colors, preparation time, machine price, speed and format into the database. A model is also proposed that includes linking the printing machine with the printing material. Thus it will be possible to make calculations that are also the elements for digital job orders.

3. Virtual printing production supported by simulation methods

By defining prepress, press and postpress norms, the area for simulating a virtual printing works is determined. It is necessary to determine the maximum production capacity of individual plants, and at what points it is necessary to engage outside printing works. Furthermore, it is possible to plan and design virtual production equipment that would be realized only in the future. This enables simulation with norm values that had been previously stored in the databases.

With the described approach we are entering an area where it is possible to open new work posts in planning and organizing graphic production, and improving and expanding the complete level of knowledge and skill. The purpose of doing simulation is evident in several large segments, namely: firstly in determining optimal workflows preceding the start-up of printing, secondly – in determining the production bottlenecks, thirdly – in investment planning, and fourthly by simulators enabling the experience of physical printing and postpress control without having any material costs. Thus it is possible to make the best solutions for certain production situations, and to have remote control of production flows.

Due to the major share of the electronic and computer parts in the digital machine value, as well as to the speedy development of electronics on the other hand, it is evident that this modern production equipment will be altered in a rather small space of time to follow. These alterations will be the reason to implement new skills and knowledge, new organization and new parameters in order to optimize the production. It is possible to implement successfully new education, new training, and new optimizing by the mere use of simulators and simulation programs on computers that we have in everyday use. Thus it will be possible to determine at once the reason of discrepancies in respect to determined values by inspection of the proposed simulated environment. With the help of simulation it is possible to design various production versions in several different printing editions. The accumulated experience in simulation and application of this method in the graphic production is evident and shown during operation.

4. Normative structure description linked with newspaper production table description

The whole model has been developed on related base norms where all operations are described as well as the graphic production recourses. Information forming the graphic production norm structure was stored in two ways. The first was by using the related database as the main information storage. We used the Microsoft SQLServer related base together with the SQLXML module. The second way was storing data in a pure XML record. The decision what to store into the usual related base records and what to store into the XML element and attribute structure depended on the requirements and the manner in which data was used. For fast query over the keys, in respect to large amounts of data, variable keys were placed into separate related base fields. Variables for calculation processes used by the application, and data that was not used for extensive research were stored inside the XML technology. It has been made possible to alter norm data during time periods. This is possible by using the advantages of related data base technologies and XML technology. They do not exclude each other but complement one another.

An XML interface was made over the related base through XMLSchema where the desired communication dictionary not equal to the names and definitions in the related database tables was determined. Thus the heterogeneous written norms were changed into an XML record over which program modules were built for processing production nodes. The XMLSchema enabled us to determine the XML document view, making the links with the related database tables and fields as well as determining related relations on the level of XML elements and attributes. This manner of realization enabled all transactions to be in the form of XML records regardless of the data source: related base tables or self-standing XML record. Figure 1 shows the norm structure of a printing production.

5. Experimental testing of the virtual edition

Simulation was performed in respect to a review magazine in such a manner that besides the number of printed copies, the edition scope was also taken into account and printing was performed on virtual equipment on sheets and rolls. The results are seen in the profitability order sequence of the machines that are part of the individual graphic production equipment in respect to individual jobs.

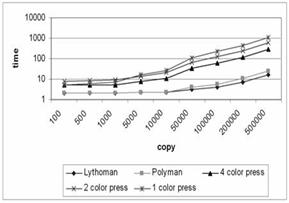

In the role printing experiment the virtual magazine review issue had 16, 32, 48, 64, 72, 86 and 112 pages. Lythoman and Polyman virtual rotation machines had been created for the experiment. The number of published copies amounted to 100, 500, 1000, 5000, 10000, 50000, 100000, 200000 and 500000. All the editions were defined in the A4 format. The cost and time period ratio (prepress, press) for both of the machines had been taken from actual production. Printing speed time and the price of the edition in all scopes and numbers of printed copies were taken for comparison purposes. In the 16-sheet scope the printing time curve shows insignificant discrepancies in the 500 copy and 1000 copy editions. The greater speed of the Lythoman in respect to Polyman is evident only when the number of copies printed amounts to 5000 and more.Analysis of the price curve shows that the Polyman machine is cheaper when printing up to 50000 copies, and over this figure Lythoman is more favorable. For all other ranges (32, 48, 64, 72, 86 and 112 pages) the necessary printing time was shorter on the Lythoman machine than on the Polyman. The price for the 32-page range was lower on the Lythoman for all the various editions. The following, 48-page scope proved to be cheaper on the Lythoman for the number of printed copies amounting to less than 5000, and Polyman proved to be cheaper when the number of printed copies was over 5000. For the 64-page edition Lythoman proved to be cheaper for all printed copy scopes, and the curves met only when the number of printed copies amounted to 500000. The assumption is that the Polyman is cheaper if the number of copies is higher than 500000.

For a 72-page magazine the Polyman is more expensive for the quantity up to 10000 printed copies, and the Lythoman when exceeding this number. The following, 86-page magazine showed the greatest difference in price when the number of printed copies amounted up to 50000 (Polyman is more expensive), and beyond this figure the price curves were significantly closer to each other, but in all cases Lythoman was still cheaper. The last, 112-page issue was more profitable printed on the Lythoman in cases of up to 50000 printed copies, and above this figure – on the Polyman machine.

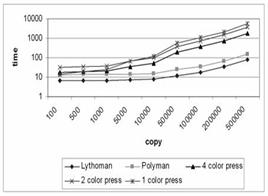

A virtual book edition printing was simulated from sheets in the experimental printing part in identical circulation and number of printed copies, as was the case for the review magazine printing. Three printing machines were created for the experiment, four-color ones, two-color ones and a single-color printing machine. The price and time period ratio were taken from actual production (prepress, press). For the scope of 16 pages in the 100-copy issue the time curves of the one-color and four-color machines had been identical, while the two-color one was the slowest. The same order sequence was shown in the 1000 copy edition, whereas the single-color machine was the slowest in the 5000 copy edition. In the edition amounting to 10000 copies, the fastest was the four-color machine, followed by the two-color machine, and the single-color machine proved to be the slowest one. The same order sequence remained up to the end of the experiment (Figure 2).

Figure 2

The same time period was needed for 32-page and 48-page scopes. The 64-page edition in 100 printed copies proved to be the fastest on the single-color machine, followed by the four-color machine and the slowest was the two-color machine. In the 500-copy edition the two-color machine remained the slowest one, followed by the single-color machine, whereas the four-color machine proved to be the fastest one. The same order sequence was for the 1000 printed copy edition, whereas the single-color machine was the slowest in the 5000-copy edition, followed by the two-color and then the four-color machines.

The above order sequence remained the same in all the experiments for 10000, 50000, 100000, 200000 and 500000 copies. The following, 72-page edition showed identical results for the single-color machine, and so was the case with the 64-page edition, whereas the time ratio in respect to the speeds of the single-color and four-color machines proved to be constantly in favor of the four-color machine. In the case of the 86-page-100 printed copy edition the single-color machine was once again the fastest one, followed by the four-color machine, whereas the two-color machine was the slowest one.

The same order sequence remained for the 500 printed copy edition, whereas the four-color machine became the fastest one in the case of the 1000 copy edition, followed by the single-color, and then the two-color one. After 5000 printed copies the order remained the same till the very end; the slowest was the single-color machine, then the two-color machine, and the four-color machine was the fastest. The order sequence for the 112-page edition was the same as for the 86-page edition (Figure 3).

Figure 3

When observing the price through all the scope combinations and numbers of printed copies, the conclusion is that the most expensive printing is always on the single-color machine. The two-color machine has proved to be more profitable as to the price only in issues up to 1000 printed copies and in the scopes of 16, 32 and 48 pages. In all the other situations the four-color machine proved to be more profitable.

In this manner the virtual printing machine giving the optimal ratio between the price and the time necessary to print individual editions was determined. This paves the way for the recommended manner of planning and determining actual jobs. There is opportunity to investigate and create one's own operation plan without unpleasant consequences, without material expenses and without actual wastages. First the benefits of the proposed configuration are proven on basis of computer simulation, and then they are realized in actual time for real.

6. Conclusion

The results obtained improve and enhance the level of production control and planning, and enable additional JDF build up. The final results are the comparative relations of condition interdependence for individual experiments. Only integrated databases supported by XML can raise communication on the highest level of openness and transparency in the adequate and interactive manner. A supplement to the work is the used group of norm settings enabling simulation to be performed. The paper compares the structure of relations between the above given variables. The goal is to create as many as possible real production situations, to store the obtained data into databases and in this manner to aim at obtaining detailed computer science descriptions of graphic production units.

Operations have shown that the simulation method gives results that raise printing processes on a new and higher computer science level. Thus it was proven that restructuring of existing plants could be carried out with a new type of graphic production organizing and planning. On basis of the obtained results supported by simulation, it is possible to predict the direction production will take, and use this information for immediate and dynamic transforming of the production to comply with new market requirements.

7. Literature references

1. K. Pap, (2003), Standardizacija i automatizcija grafičke proizvodnje u XML-u, Znanstveno stručni skup o pravcima razvoja grafičke industrije I tiskarstva, Stubičke toplice, Croatia

2. M. Žagar, V. Žiljak, Z. Sabati, K. Pap, (2003), Proposal for XML Technology Programming Solutions in the Printing Business Informix database, IIS 2003 Procedings, Varaždin, Croatia

3. V. Žiljak, K. Pap, D. Agić, I. Žiljak, (2002), Modelling and Simulation of Integration of Web system, Digital and Conventional Printing, 29th International Research Conference of IARIGAI, Lake of Lucerne, Switzerland

4. V. Žiljak, (2003), Managing the graphic production with xml technology, Međunarodni simpozij “Ofsetni tisak”, Zagreb, Croatia

5. V. Žiljak, (2003), Digital Printing and XML Technology in Graphic Production Planning, International Conference on innovative educational content management and Digital Printing: Proceedings, Athens, Greece

6. V. Žiljak, A. Koren, (2003), Modelling and Simulation as a Planning Method for Printing Houses Modernitazation with JDF, IIS 2003 Proceedings, Varaždin, Croatia

7. Z. Nježić, V. Žiljak, K. Pap, B. Sviličić, (2003), The stohastic model of simulation of a virtual printing-house, 30th International Research Conference of IARIGAI, Dubrovnik, Croatia