Photo 1. Folding cardboard box and its blank

Photo 1. Folding cardboard box and its blank

2. Introduction

Research on the quality of grooves obtained in the process of making box blanks on folding cardboard boxes has demonstrated that the groove quality is dependent on channel type, its dimensions, quality of the material used, the strength of the pressure applied, and cardboard type and quality. The research has established that the cardboard humidity has a special in. uence on the quality of grooves. Even though the aesthetic appearance of the grooves must not be neglected, especially with decorative boxes designed to hold cosmetic products, the groove quality is also a technologically defined concept enabling us to design boxes quickly, correctly and in a technologically satisfying manner. It is well known that decorative packaging can act as a so-called silent salesman , so the appearances are very important. These boxes are frequently varnished and mounted with metal foils. The usual cardboard humidity is between 35 and 40%, but it is not easy to achieve the same designated humidity in all the installations where such box blanks on folding cardboard boxes are produced. Since the humidity changes overnight, it is a frequent case that the humidity of cardboard boxes of the same edition varies. The aim of our research is to establish the extent of the in. uence of humidity on groove quality. Throughout the research we applied the established rule on representing grooving quality through numeric values. At the end, we will be able to recommend to the graphic industry the best climate conditioning of cardboard boxes, which could provide for the nicest high-quality grooves. All the groves obtained are recorded by a microscope in order to observe as closely as possible the fibre deformation caused in the grooving process and to get the most precise results.

Photo 2. Punching tools

3. METHODS AND MATERIAL USED

We based the research on the most frequent quantities of grammes per square meter used in the production of small folding cardboard boxes closed by pinning. To make the research more transparent, all the boxes used were of the same manufacturer. The uniformity of material tested meant the trustworthiness of the results. We chose cardboard of BELPAK – BEL/GT 1 quality manufactured by KOLIČEVO, Slovenia. The cardboard samples were weighing 280, 320, 350, and 450 g/m 2 . Those samples were cut into 100×200 mm sheets and grooved all along the shorter side in order to observe the groove quality sideways. Ten samples were made of each cardboard type and the grooving quality was assessed parallelly and perpendicularly to the fibredirection. In other words, twenty samples of each weight (g/m 2 ) were tested. Since we wanted to test the impact of cardboard humidity on groove quality, we used the same grooving band with all the samples. In accordance with previous research, the

4. TEST RESULTS

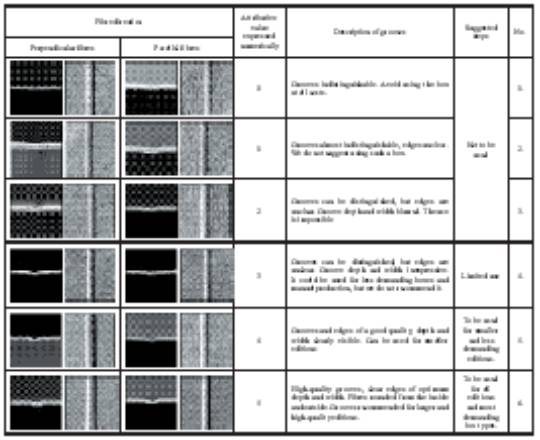

Test results are given in table 1 and diagram 2 shows the comparison between the results from table 1 and the suggested evaluation system from table 2.

Table 1. Test results

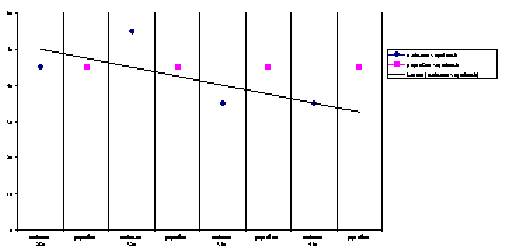

Diagram 1. Graphic presentation of the impact of cardboard humidity on groove quality and of diminishing humidity levels with heavier cardboard

The tests showed that optimum results for grooves perpendicular to the fibre direction were obtained with the humidity of 45%, regardless of the sample weight (g/m 2 ), while those parallel to the fibredirection needed more humidity for smaller weight (the best results for cardboard weighing 280 g/m 2 were obtained with the humidity of 45%, while 320-g/m 2 cardboard requires the humidity of 55% for the optimum groove quality). On the other hand, heavier cardboard needs less humidity (cardboard of 350 g/m 2 and 450 g/m 2 need no more than 35%-humidity for the optimum groove quality). Diagram 1. shows diminishing humidity levels with heavier cardboard.

5. CONCLUSION

The research demonstrated that cardboard humidity levels in. uence the appearance and the quality of grooves. It is necessary to de. ne the optimum humidity level for each cardboard type in order to achieve good results in practice. The authors wish to underline the fact that the appearance of grooves largely depends on the fibredirection, which, in turn, depends on cardboard humidity. It is a frequent case in installations, especially with large manufacturers of cardboard boxes, that cardboard types are present at the same time, simply because the orders are not usually carried out separately. Therefore, the authors can recommend the constant humidity level of 45%, which suits almost all cardboard types. We also feel obliged to stress that no modern installation for finishing processes in cardboard production should be without a central humidifying system. It is also necessary to have a humidity maintenance system in order to prevent environmental humidity from in. uencing cardboard humidity every time an installation door opens.

6. Bibliography

1. A. Strecker, D. Berndt: Komentar zur Verpackungsverordnung , Verlag Recht und Wirtschaft, Heidelberg, 1992.

2. H. J. Tenzer, F. Hesse: Verpackungsmittel aus Papier, Karton und Pappe , VEB Fachbuchverlag, Leipzig, 1971.

3. T. H. Tenzer: Leitfaden der Papierverarbeitungstechnik, VEB Fachbuchverlag , Leipzig, 1989.

4. xxxxxxxxx: Encyclopedia of Packaging Technology, John Wiley & Sons, Inc., New York , 1997.