TESTING COLOR ACCURACY OF PDF FILES

Mahović Sanja, Agić Darko, Žvorc Dean

Abstract:

Adobe Portable Document Format (PDF) is common used for digital exchange. The PDF overcomes several of the limitations of

the PostScript language. A PDF file is designed to be viewed on screen as well as print, and this makes it possible to check the page content before imaging onto hard copy. The aim of this research is to check the reproduction of colors via output systems such as proofers. In experiment different inkjet and laser printers were used. Two target tests were printed on different digital output devices. The Altona Measure and Altona Visual Targets contain all neccessary elements for checking compliance and colour accuracy and to identify product limitations. Tests are measured with the aim of spectrophotometric and visual judgement.

Key words:

Portable Document Format, color accuracy, proof

1 Introduction

The Portable Document Format (PDF) was created for exchange of digital data across a wide variety of machine configurations, operating systems and communication networks. Despite the support of graphics industry vendors, PDF did not gain rapid acceptance as a format for the submission of digital files to printers and publishers. The PDF files did get exhibited many problems, like missing fonts and low-resolution images, making them worthless for high–quality print production (Marin, 2003).

The PDF is based on the same imaging model as PostScript, and it incorporates the majority of PostScript operators. The structure of a PDF file is like a database of the object, instead of a program that has to be executed in order to render a page description. A PDF file consists of a header, a body, a cross-reference table and a trailer. The body takes the place of the script in a PostScript file, and it contains a sequence of numbered objects that represents all the text, graphics and images in the document (Green, 1999). A PostScript file is converted to PDF with Acrobat Distiller. Job options are set in Distiller to control compression, font embedding, and high-end options such as Open Prepress Interface (OPI), overprint settings and color processing. Distiller offers a range of compression options according to the type of object and the quality requirements. These are highly efficient, and the process of conversion from PostScript to PDF usually reduces the file size dramaticaly. It can then be viewed with Acrobat Reader. PDF files are also intended for use as a means of distibuting documents in electronic form, and they have a range of multimedia capabilities such as sound and video.

Acrobat Exchange, with its open architecture, allowed for the development of plug-ins to enhance PDF capabilities for the printing industry. These documents should be viewable on any display and should be printable on any modern printer. With improvoments, PDF files become widely used. PDF files are platform-independent, it can be viewed on any of the most common platforms in use including Mac and Windows. They eliminate the need for layout applications.

2 Experiment

The Altona Test Suite consists of a set of PDF files, specially designed for testing digital output devices – in particular, proofing solutions, conventional and digital printing systems. The purpose of the Altona Test Suite is to check PDF/X-3 compliance and color accuracy for all software and hardware modules used in a composite PDF workflow for print production. (www.eci.org). The Altona Test Suite comprises three PDF-files each designed for specific purposes. Two target tests were used, Altona Measure and Altona Visual. They were printed on free printers, laser printer-HP 8500 DN, and two ink-jet printers (HP designjet 10PS and Epson 9600 – both use Best RIP). They were printed on glossy paper. We printed tests also on mat and semi mat paper (Epson 9600).

“Altona_Measure.pdf”

contains test elements for setting up and checking output systems such as proofers or conventional or digital printing systems. These charts were measured with spectrophotometer.

“Altona Visual”

is a PDF/X-3 file focusing on visual testing of the PDF/X-3 applicability. As PDF/X-3 allows a color-managed workflow, this page comprises not only CMYK and spot color elements, but also several components containing device independent colors such as

CIELL*a*b* and ICC based RGB. The Altona Test Suite addresses a set of six criteria well known for being critical in proofing and print production of PDF/X-3 files. For the evaluation of each criterion several elements are to be taken into consideration. For easy reference, numbers has marked all elements. The criteria for visual evaluation are process color, duotone and spot color, device independent color, overprinting, smooth shades and resolution.

This test charts were printed from three different programms, Acrobat, Photoshop and Quark. Thirty students were visually judged. An ordinal scale is used (M. Fairchild, 1997), numbered from one to six, for checking elements 19-25 and 39.

3 Results

Altona Measure test was measured with spectrophotometer Spectrolino (Gretag). The measured data are presented in Table 1.

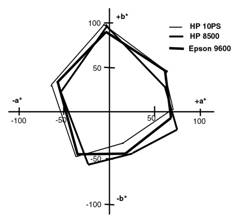

After measurement, we were consrtructed device gamut which are shown in Figure 1.

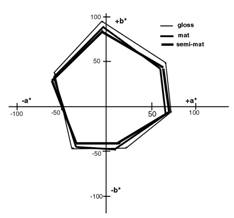

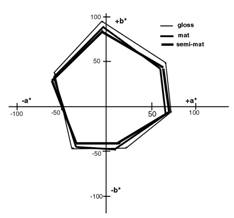

We checked whether gamut is changing a lot with using different type of paper and it is shown in Figure 2.

Figure 1 Printer`s gamut

Figure2 Changing gamut with paper

Duotone image (26, spot color-orange and process color black, was created in Adobe Photoshop. A small blue square in the upper right corner that indicates that the system is not able to correctly deal with spot colors appears on test printed on HP 10PS and HP 85000.

Marked elements 22 and 24 are used for testing PDF/X-3 functionalitty. A cross shaped section in the centre of the motif contains an RGB image. The image was assigned an embedded source ICC profile (ECI-RGB) and the perceptual rendering intent. The rest of the image is in CMYK mode. There are noticeable color

difference in the centered cross shaped section on test printed on Epson 9600 (all papers). This indicate that the respective system does not support color transforms as defined in PDF/X-3. In the case of cross shaped section in neutral image (22), all prints were acceptable. The purpose of the five patches (34-38) is to check weather or not rendereing intents and source profiles of a PDF/X-3 file are processed correctly. Each square consists of four triangular sections marked by small elements (rhomb, square, circle and triangle)Light gray strokes from underneath leading into the patches 36,37 and 38 indicate along which virtual line noticeable color differences shall be visible in correct output. The segments are coded in the color spaces CIELab and ECI-RGB in such a way as to match colorimetric identical colors. As all four segments have been assigned the relative colorimetric rendering intent (RI) no distinct color differences should be visible. A distinct color difference betweeen ECI-RGB and CIELab after conversion to the CMYK destination color space indicates an error, as both color spaces should be treated identically. Color differences between elements – vector versus pixel – within the same color mode indicate an unwanted difference during color conversions of vector and pixel elements.

Purpose of ECI-RGB and CMYK (34) element is to check whether or not the

color transformation of device independent colot into the CMYK color space of the output intent matches the result of the same conversion carried out in Adobe Photoshop.

Different device independent color spaces (35) is used for checking whether the color transformation of different device independant color spaces produce identical color results.

The patches 36 and 38 are used for checking whether the rendering intent (perceptual and relative) is correctly taken into account during color conversions into the destination color space.

The patch 36 is entended for the evaluation of the consistency of color transformations to the destination color space based on colors characterized by different ICC source profile.

|

Â

|

Patch 34

|

Patch 35

|

Patch36

|

Patch 37

|

Patch 38

|

|

HP 10PS-gloss

|

Ă–

|

Ă–

|

Ă–

|

-

|

Ă–

|

|

HP 8500-gloss

|

Ă–

|

-

|

Ă–

|

Ă–

|

Ă–

|

|

Epson-gloss

|

-

|

-

|

-

|

-

|

Ă–

|

|

Epson-mat

|

-

|

-

|

-

|

-

|

Ă–

|

|

Epson -semimat

|

-

|

-

|

-

|

-

|

Ă–

|

Table 2. Results for color management patches

Overprinting patch 28 consists of three circles colored with solids of the process colors: yellow, magenta and cyan. Printed test on Epson 9600 has correct overprint simulation. HP 10PS has partly wrong simulation of process colors and partly wrong simulation, and HP85000 has missing overprint simulation.

The quality of gradients and the support of PostScript3 smooth shadows are visually evaulated as good on all printed tests.

The gray background (19) consists of all four process colors (c25m19y19k20) were visually checked for color casts and wrongly adjusted overall gradation. All prints give satisfactory results. The conrast is good only on print that is printed on HP 10PS, other printers haven`t get good contrast.

The portrait skin tones is reproduced correctly on HP 10PS, sufficient with Epson 9600. Laser printer HP 8500 is failed down in reproduction of skin tones. Neutral colors (22) are good reproduced with all printers.Images from 23-25 contain high light tonal reproduction, saturated

colors and the dark areas. The results are presented in figure 3.

Figure3. Subjective assesement derived by using ordinal scales

4 Discussion

The results showed that reproduction of neutral colors is satisfatory on every print Also the visual difference between inkjet and laser printer is still big. RIP that printer used influences on the reproduction,with the use of better RIP more elements were correctly reproduced. Laser printer had wrong printing simulation, the system can not correctly deal with spot colors. Although laser printer had good contrast, the colors are not reproduce well specially skin tone and highlight. For proofing better inkjet printers achieved better quality. There is not significant visual dependence of the type of paper used.

5 Conclusion

Testing two targets on different systems, indicats that processing PDF files is different on different

printers, support with appropriate profile, and it is given different results. Although PDF files are independent on various platforms, they are rather dependent on output device. The need for improvement of the ripping for the target device is necessary, and it appears that inkjet output devices show better color matching according to the original.

6 References

Green, P.(1999).

Undestanding DigitalColor

Pira International, 1-85802-450-1, Pittsburg

Marin, J.

&Shaffer, J. (12003).

The PDF Print Production Guide GATF Press, 0-88362-431-1, Sewickey

www.eci.org