Abstract :

This work gives proposal for the systematic database creation with the values for individual exploitation situations and with interrelations of possibly working flows. The goal was to be closest as it can be to optimal production management process in the system with many modalities to reach solving solution. Input simulation values are solved as XML native database which objective is to crate activation of multiple experiments and results that are prepared for automatic analysis. Last objective of this work is development of new methods for improvement of Post-Press planning with simulation methods.

Key words: organising digital normative provisions, improvement of Post-Press, simulation methods

1 Introduction

The Post-Press was marginal point for many printer-houses. During the organizing processes of the digital normative provisions as the base for computerized management of the finishing activities in printer-houses arises to many unknown situations. This work gives proposal for the systematic database creation with the values for individual exploitation situations and with interrelations of possibly working flows. The goal was to be closest as it can be to optimal production management process in the system with many modalities to reach solving solution. On relational database SQL server, the XML technology became new communication interface between a base of normative provisions and planed simulation experiments for the main work flows of planning execution activities of the finishing in Post-Press. Experimental design of calculations is based on detailed digital normative provisions database of finishing processes, which incorporates times and prices for execution process of individual production activities. Input simulation values are solved as XML native database which objective is to crate activation of multiple experiments and results that are prepared for automatic analysis. Last objective of this work is development of new methods for improvement of Post-Press planning with simulation methods.

2 General situation

Graphical production today became one of the most profitable industry and lives artisans’ fields. Complex systems of graphical industry introduce integration and automation because of necessity to reduce work execution time. Ending goal of this kind of development is continuing automatic production, financial work processing, work monitoring, and financial work analysis. The XML (eXtensible Mark-up Language) was recognized as new language of information description and transferring between applications and systems from various producers (manufacturers or makers). That provides creations of individual solutions in automation of graphical production. Only provision for these systems is that devices and applications know XML communication dictionary. This is way to make easy developments in future, because of various XML characteristics, like its possibility to adopt new dictionaries into existing ones. Why to develop new dictionary if exists developed one? Programming model “Webposkok” was developed by authors from Faculty of Graphic Engineering in Zagreb and has these premises. With this model it is now possible to create phases of graphical production on various devices and capacities. Only provision for that is to make normative provision description of all production process factors. The whole model was established on normative provision basis, where all operations and capacities were described in detail. The model is in fact one web application and this is its main characteristics. Interfaces for working with all normative provisions, before calculations, calculations, and digital working orders became reachable to various groups of users on that way. Normative provisions database is filling up almost one year and existing data provides complex analysis and conclusion making. In this work researching goal is situation where we have to make decision about parallel usage of second machine for rolling. These machines have different characteristics, from velocity parameters to working hour price. Usually it is not clear for which editions to make best (adequate) decision, and it is not always clear even financial aspect of that decision. Goal is to accomplish graphs of execution velocities and of financial analysis of that decision

3 Normative provisions of graphical production database

Normative provisions of graphical production are saving into relational database and in XML records. Decision about what to save into classical records, what into XML elements and attributes depends on application demands and on analyst requests which are using these data. For faster searches (query) by keys it is better to put variables of keys into separate fields of relational database. Variables for calculative processes that are using by application are better to save into XML technology. Normative provisions must be changeable during the whole period (of time). It is reachable with exploration of benefits given from relational databases technology and XML technology. These technologies don’t exclude each other but they are extension of each other. Reliable and stable relational database was constructed with MSSQL Server Database and with XML interface throughout XML Scheme, into which requested communication dictionary can be defined and which is not with equal names and definitions of tables into its relational database. On that way different sorts of normative provisions are transforming into unambiguous record which have developed programming modules for production knot processing. XML Scheme provides us with definition possibilities of look up of XML documents, with establishment of table and field connections into relational database, and with definition possibilities of relations on the level of XML elements and attributes.

4 Model of machine for rolling up sheet paper

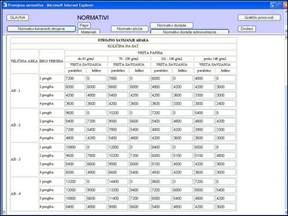

Model of machine for rolling up sheet paper in “WebPoskok” was represented with tables XSLT technology from XML which holds all normative provisions of that machine. Normative provisions set of that machine consists from these variables: paper sort, format of sheet, type of rolling up, number of bends, time for machine preparation according to number of bends, time for exchanging the same set of panels, machine preparation working hour price, machine working hour price. These prices are in relation with today developments of these machines. On figure 1 we can see XML normative provisions model of machine for rolling up sheet paper. We make interface into XSL technology (figure 2) to have possibility to make experiments with normative provisions parameters. XSL (eXtensible Stylesheet Language) language define XML document look for dedicated technology of representation, and concretely here we have HTML language for representation browser. Representation of data was not defined into XML document and into XML Scheme. XSL technology is one of basic principles why content is completely separated from representation..

Figure 1. XML normative provisions model of machine for rolling up sheet paper (in Croatian)

Figure 2. XSLT interface for normative provisions processing (in Croatian)

5 Model solution with XML tehnology

Developed XML model for calculation of time and printing price was presented from authors during the last year [4]. Model has all options in production that are needed for accomplishing someone of finished products. That are XML elements as identification name of calculating experiment, ID of printing machine which is prepared for printing, ID of selected paper, ID of selected offset panel, normative provision ponder for velocity of printing, defined edition of work, number of work pages, format of work page, format of printing sheet, number of colours from front and number of colours from opposite side of page, and number of pages on sheet paper. Experimental results are on the same XML document, and analysed model variables have results presented on clear and unique manner. Resulted XML elements which are calculating and recording into XML document are, for example: edition of sheet paper, planed edition of sheet paper with incorporated technological and finishing addition, number of panels, time of machine preparation, time of machine cleaning, time of printing, total needed time for finalisation of product edition, papers costs, colours costs, panels costs, total price of product edition, and product unit price. PostPress experimental calculative data are in table of total calculation as XML document, and they can be separately researched and used for experiments.

6 Experimenting with model

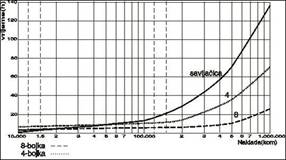

Introduction of additional and identically processing knot into production is usual idea in planning of production, when goal is to have better permeability (capacity) of specific (working) operation. Decision about when to duplicate capacities of one finishing process, or for which editions of specific work, is crucial question. Second thing is how much is that financially profitable in relation to ending price of product. Experimental measuring is taken on model for work: leaflet (flyer) A4, 4/4, from B1, 135 grams paper, and colour coverage 50% with to parallel rolling up. Measuring is taken for editions from 500 to 1,000,000; and with machines with normative provisions: 4-colours, 8-colours and on machine for rolling up. Eight-colour machine has in process duplex modulo. Conclusion was that region of measuring interest was upper editions from 10,000; because it was clear that under that limit we can’t make optimal decisions. On graph in figure 3 are curves of times needed for accomplishing specific printing and finishing phase

Legend: vrijeme(h) = time(h); naklada(kom) = edition(peaces);

4-bojka = 4-colours; 8-bojka = 8-colours; savijačica = rolling up.

Figure 3. Times needed for accomplishing specific printing and finishing phase (in Croatian)

At edition of 20000 printing phase 8-colour machine finished in the same time as finishing phase of rolling up machine. The same thing happened for 4-colour machine at edition of 50000. These crossings are momentums when we have to decide to introduce into production chain one more rolling up machine in finishing phase, because above these editions finishing phase of rolling up is bottle neck of production.

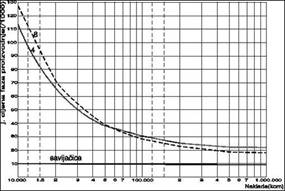

Legend: J. cijena faze proizvodnje(/1000) = unit price of production phase (/1000) naklada(kom) = edition(peaces); savijačica = rolling up.

Figure 4. Unit price of production phase (in Croatian)

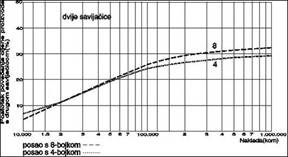

Legend: Postotak povećanja cijene proizvoda s drugom savijačicom(%) = Percent

of increasing product price with another rolling up machine(%);

posao s 8(4)-bojkom = work with 8(4)-colours machine;

naklada(kom) = edition(peaces); dvije savijačice = two rolling up machines.

Figure 5. Percent of increasing product price with another rolling up machine (in Croatian)

On graph in figure 4 is unit price of production phases of printing and finishing. For printing phases it is presented two times, once when work was printed on 4-colour machine and second time if printing work was on 8-colour machine. On that way we can see share of price in finishing phase of one rolling up machine in relation to printing phase. Third graph on figure 5 presents percent of increasing product price that was made with two rolling up machines and with 8-colour machine in one variant, but in another variant with 4-colour machine. This graph can be used for price correction in final offer (bid), because after deciding to introduce another rolling up machine (that product has concurrent time of its finalisation for market) unknown thing is value of that product. If product can’t have higher price on market then we know which distribution is of internal costs (spending)

7 Conclusion

This work has the goal to accomplish closeness to optimal management of production and solving of dedicated problem in that production in relation with organised digital normative provisions described in relational database and XML data files. Developed model was based on relational database where all necessary normative provisions and prices are saved, and which have developed XML system with XML Schemes. Data acquisition in relational database and acquisition in XML data is accomplishing throughout XSLT technology, as presenting and interfacing technology with goal to work throughout browser. Here, on example with one concretely task to make optimally doubling of one PostPress machine in graphic production experimentally was researched and developed financial and time analysis of that decision. This method for improvement of PostPress planning speeds up production decisions and presentations of their financial consequences.

8 References

[1] Pap, K. (2003). Standards During the Whole Printing Process Production (published in Croatian), International symposium "Offset printing", Zagreb.

[2] Pap, K. (2003). Standardisation and Automation of Graphic Production in XML (published in Croatian), International symposium "Offset printing", Zagreb.

[3] Žiljak, V. (1982). Simulation with Computer (published in Croatian), School Book, Zagreb.

[4] Žiljak, V., Pap, K., & Šimović, V. (2003). The Simulation of Integrated Conventional and Digital Entrepreneurship System Models with the Financial Parameters, in Loistl, O., Veverka, A., Šimović, V., and G. E. Lasker eds.: Special focus symposium on Catallactics: Quantitative Modelling of Human Market Interactions at the 15th International Conference on System Research, Informatics and Cybernetics: InterSymp-2003, (pp. 33-42), Baden-Baden.